Liquefied Natural Gas (LNG)

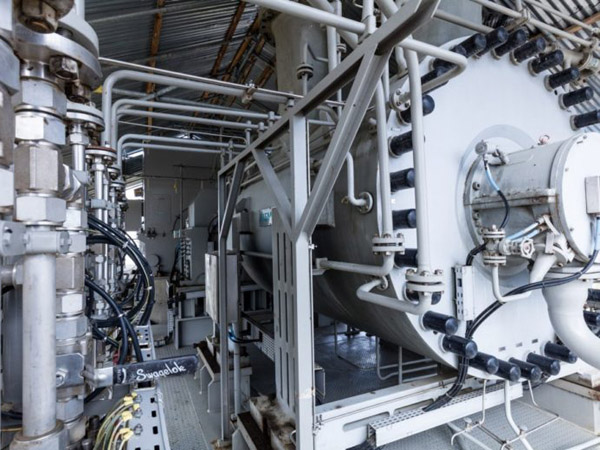

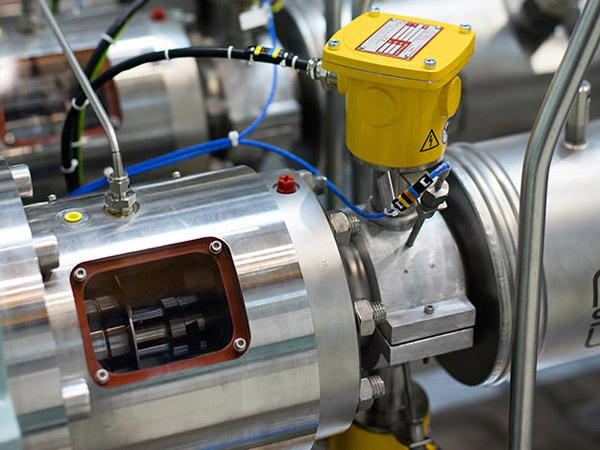

BANGLAMARK provides every scope of services in the construction of storage tanks and handling facilities for low-temperature liquefied substances such as LNG, Ethylene, Ammonia, Oxygen, Nitrogen, Hydrogen, Etc. (Low temperature ranging from -4 °c to -196°c). we have the resources and expert foreign Engineers to design and build LNG storage tanks in any location and under all types of logistical constraints. Our people have the localized knowledge to provide front-end permitting and regulatory compliance support all the way through startup. We direct-hire and train local field personnel whenever possible, and we can quickly mobilize large erection crews anywhere if they are needed. As a dedicated storage tank manufacturer, we offer full-process EPC (engineering, procurement and construction) including maintenance to achieve high-performance project execution for tanks and auxiliary equipment/facilities while leveraging the pricing and geographical advantages of manufacturing products.

About the LNG Terminal Liquefied natural gas terminal is a structure for liquefied natural gas to store. It can comprise special tanks, ships or even building structures. Port infrastructures and pipelines are also a part of LNG terminals

Meet Our Experts

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |

| Liquefied Natural Gas (LNG) value chain...!!! |