Dredging Equipment

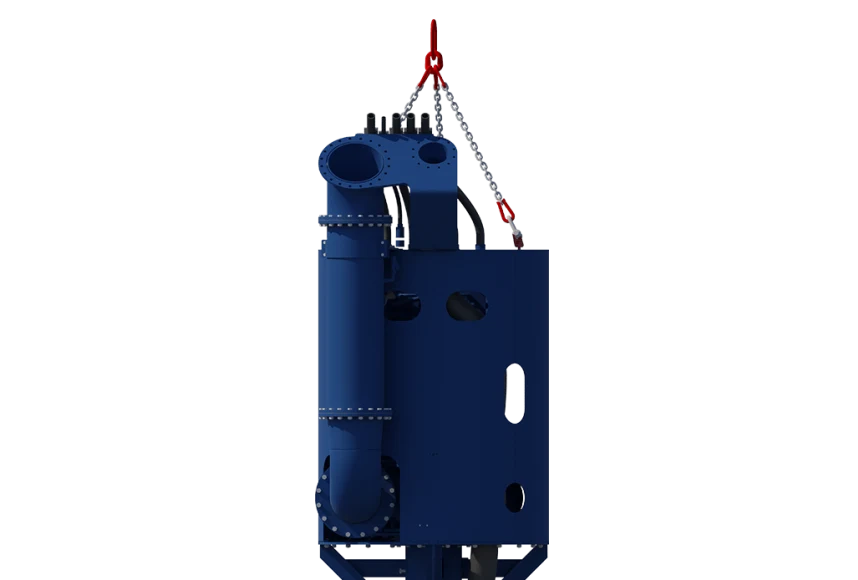

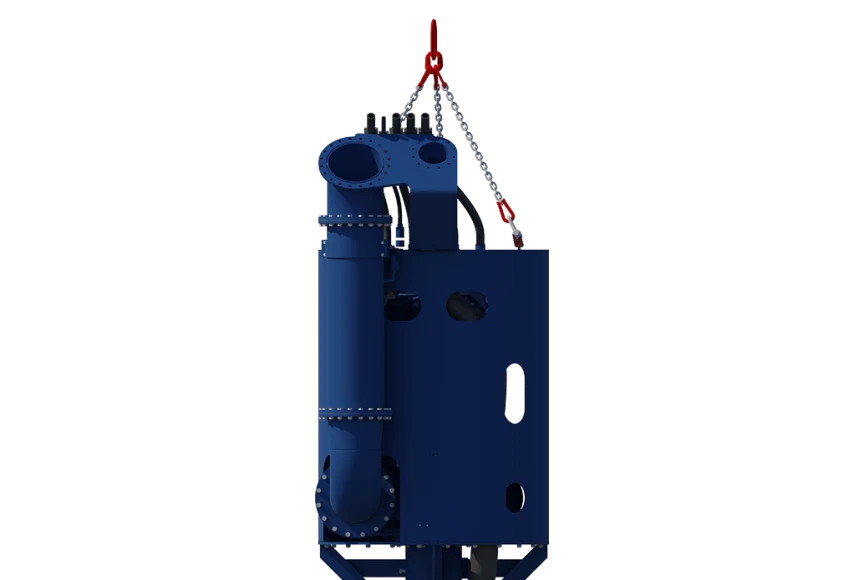

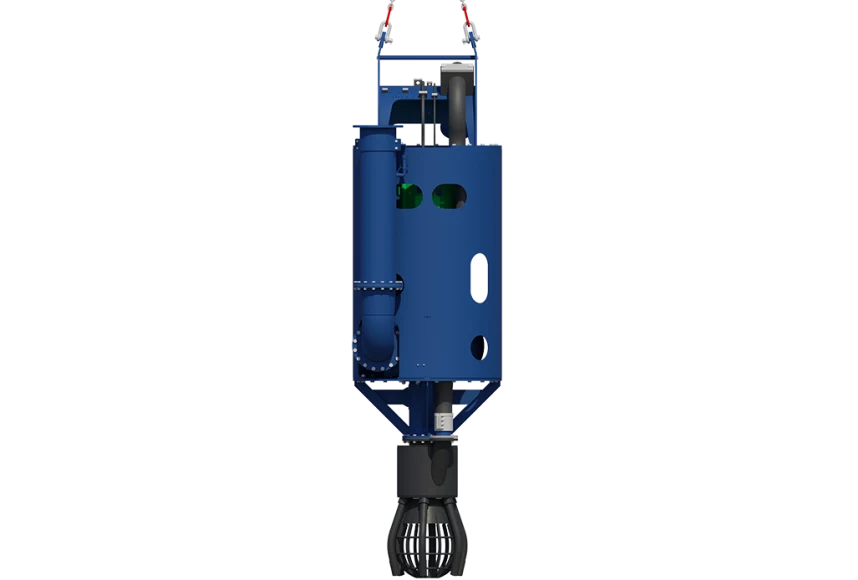

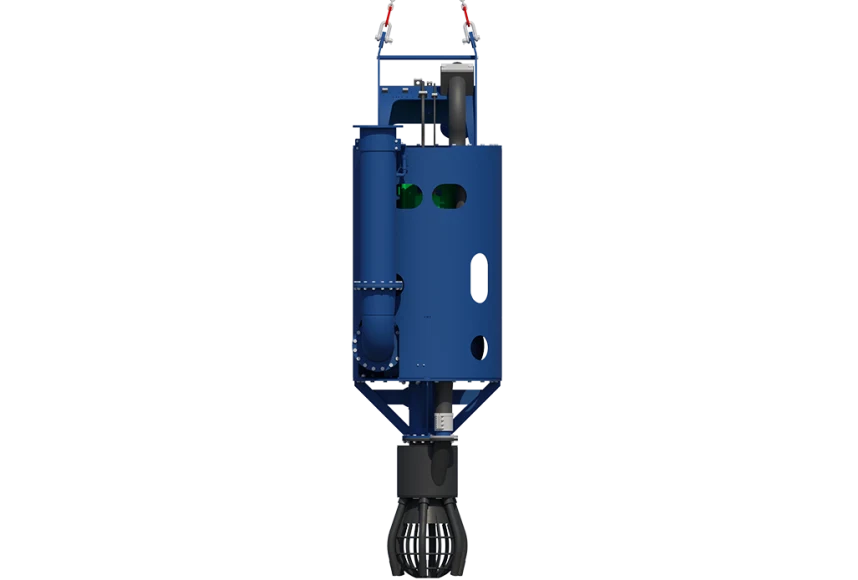

DOP submersible dredge pumps

A versatile submersed dredge pump

The flexible and cost-effective DOP dredge pump has been designed for pumping a high-concentration mixture. Whether pumping sand, cleaning a tailings dam or removing silt from a pond – the DOP pump does the job due to its exchangeable suction heads. As an excavator dredge pump attachment or as a standalone dredge, find out what the DOP dredging pump can do for you.

Dredging components

Dredge Pumps

Dredging instrumentation

Maximise your dredge production

Whether for a retrofit or a newbuild, a production measurement system ensures that you are not dredging in the dark. A density meter, combined with a velocity meter, offers the dredge master accurate, clearly presented, real-time data about the dredger’s production. Maximised operational efficiency is the result.

Fit for any dredger

Whatever the type of dredger or dredging tool – cutter suction dredger, hopper dredger or just a small submersible dredge pump – the operator has to know what he is doing. Production measurement equipment offers exactly what a dredge master needs: accurate, real-time data of the throughput in the dredge pipeline. The data can be presented on a screen or an analogue meter, depending on your requirements.

Optimised operations

Accurate production data ensures that the dredge operator obtains a clear insight into the dredging process. Therefore the efficiency of the operation can be increased.

Real-time production data

A production management system gives the dredge operator continuous feedback on the dredging operation. The mixture density and the flow velocity are measured in the dredge pipeline. These data are fed into the system, which enables the operator to actively adjust the operation of the dredger to achieve an optimal production.

Clear visualisation

Real-time production is shown on the screen, using a yield indicator. Alongside this, counters show the daily and weekly volumes dredged. When required, a separate analogue cross-needle indicator can be delivered as well for mounting in the dredging desk.

Newbuild or retrofit

Whatever your type of dredger and whatever its age, production efficiency is vital. The combined density and flow measurement system, which can be mounted in both a horizontal and a vertical pipeline, will allow the operator to actively intervene to ensure a smooth dredging process.

No fuss density measurement

The practical advantage of a non-radioactive production measurement system, is that no permits or licences are required. Gone are the long waits for paperwork and carefully planned transports. Moreover, all crew members are allowed to work with the system without the need for special training.

Accurate completion of any dredge job

The positioning visualisation system offers the dredge master a real-time overview of the exact location of the drag head, cutter unit or suction head. The system keeps track of the soil that has already been dredged on the survey map, bringing a halt to costly underdredging or overdredging.

Fit for any dredger

Whether a stationary suction dredger, a Trailing Suction Hopper Dredger or an excavator, accurate dredging is the way to a profitable dredge job. Using angle transmitters and GPS positioning, the exact position of the digging tool can be calculated. This position is then mapped in a predefined environment, allowing the dredge master to accurately dredge as per the contract terms.

Put your vessel on a chart

Mapping the position of your dredger on a predefined chart, ensures that the dredge operator knows exactly what to do. The chart shows real-time performance by changing colour when the chart depth has been reached, and when the dredge master still has to clear a layer of soil. As a result the efficiency of the dredge operation can be increased.

Retrofit or newbuild

Customised packages are available, including the software package with an industrial PC, plus a number of optionals. These may include inclinometers, angle transmitters or draught transmitters which are required for the calculation of the exact 3D position of the suction head.

At your fingertips

The dredge operator can monitor the progress of the dredge job on screen. Various views are available to facilitate different jobs. The survey map on the screen clearly shows the predefined dredging area, the boundaries and area topography.

Optimised hydrographic system

The configuration of the hydrographic presentation and the positioning system can be optimised to suit your dredger and the job at hand perfectly. It can be used for various types of dredging works, plus dumping and ground levelling jobs.

GPS with reference signals

The dredger is pinpointed on the map through a DGNSS Global Positioning System or a DGNSS-RTK position receiver. The RTK reference signals can be used to increase position accuracy.

Reliable, stand-alone dredge monitoring system

The dredge monitoring system provides operators with a real-time overview of a Trailing Suction Hopper Dredger’s dredging process. The highly flexible system is customised according to the vessel’s operational profile. It supports the dredge control system and increases operational efficiency.

Reliable and fuel-efficient system

Hopper dredgers can be fitted out with the dredge monitoring system. It provides the dredge master with a clear overview of the location of the trailing pipe, the various stages of the hopper loading process, the dredge pump production, and a logging and reporting module. The system consists of separate modules, which can be added as required in line with the vessel’s operations.

Trailing pipe position visualisation

The basic module of the dredge monitoring system is the trailing pipe position visualisation. Using inclinometers on the hinges, the exact drag head position and dredging depth is calculated and visualised. All other modules can easily be added, further enhancing the hopper dredger’s operations.

Flexible system configuration

The hopper dredge monitoring system is visualised on one screen, using an industrial PC running on Windows OS. The highly flexible system can be shown on multiple screens and in multiple locations, other modules can be added, and screens can be personalised by selecting specific preferred fields.

For retrofits and newbuilds

Both newbuild hoppers and existing ones can be fitted out with the dredge monitoring system. As a complete instrumentation package not only are the software and PC delivered, but also the various sensors for the trailing pipe hinges, the vessel’s draught, the positions of the gantries, swell compensator and overflows – the complete package.

Logging with data string output

All data in the trailing pipe module, loading module and production module can be logged. Combined with dredging statuses and tank volumes, accurate daily reports can be made. These can be sent to the relevant authorities when required to track the progress of the dredging work, or they can be used to optimise the overall dredging process.

Operational practicalities

The dredge monitoring system offers the possibility of investigating the sensor diagnostics. The operator can pinpoint the exact location of a signal failure. Moreover, remote access is integrated in the system; Damen Services can assist the operator when required. As a result, assistance is fast and cost-effective, reducing downtime to a minimum.

Production Measurement

Maximise your dredge production

Whether for a retrofit or a newbuild, a production measurement system ensures that you are not dredging in the dark. A density meter, combined with a velocity meter, offers the dredge master accurate, clearly presented, real-time data about the dredger’s production. Maximised operational efficiency is the result.

Fit for any dredger

Whatever the type of dredger or dredging tool – cutter suction dredger, hopper dredger or just a small submersible dredge pump – the operator has to know what he is doing. Production measurement equipment offers exactly what a dredge master needs: accurate, real-time data of the throughput in the dredge pipeline. The data can be presented on a screen or an analogue meter, depending on your requirements.

Optimised operations

Accurate production data ensures that the dredge operator obtains a clear insight into the dredging process. Therefore the efficiency of the operation can be increased.

Real-time production data

A production management system gives the dredge operator continuous feedback on the dredging operation. The mixture density and the flow velocity are measured in the dredge pipeline. These data are fed into the system, which enables the operator to actively adjust the operation of the dredger to achieve an optimal production.

Clear visualisation

Real-time production is shown on the screen, using a yield indicator. Alongside this, counters show the daily and weekly volumes dredged. When required, a separate analogue cross-needle indicator can be delivered as well for mounting in the dredging desk.

Newbuild or retrofit

Whatever your type of dredger and whatever its age, production efficiency is vital. The combined density and flow measurement system, which can be mounted in both a horizontal and a vertical pipeline, will allow the operator to actively intervene to ensure a smooth dredging process.

No fuss density measurement

The practical advantage of a non-radioactive production measurement system, is that no permits or licences are required. Gone are the long waits for paperwork and carefully planned transports. Moreover, all crew members are allowed to work with the system without the need for special training.

Position visualisation and survey

Accurate completion of any dredge job

The positioning visualisation system offers the dredge master a real-time overview of the exact location of the drag head, cutter unit or suction head. The system keeps track of the soil that has already been dredged on the survey map, bringing a halt to costly underdredging or overdredging.

Fit for any dredger

Whether a stationary suction dredger, a Trailing Suction Hopper Dredger or an excavator, accurate dredging is the way to a profitable dredge job. Using angle transmitters and GPS positioning, the exact position of the digging tool can be calculated. This position is then mapped in a predefined environment, allowing the dredge master to accurately dredge as per the contract terms.

Put your vessel on a chart

Mapping the position of your dredger on a predefined chart, ensures that the dredge operator knows exactly what to do. The chart shows real-time performance by changing colour when the chart depth has been reached, and when the dredge master still has to clear a layer of soil. As a result the efficiency of the dredge operation can be increased.

Retrofit or newbuild

Customised packages are available, including the software package with an industrial PC, plus a number of optionals. These may include inclinometers, angle transmitters or draught transmitters which are required for the calculation of the exact 3D position of the suction head.

At your fingertips

The dredge operator can monitor the progress of the dredge job on screen. Various views are available to facilitate different jobs. The survey map on the screen clearly shows the predefined dredging area, the boundaries and area topography.

Optimised hydrographic system

The configuration of the hydrographic presentation and the positioning system can be optimised to suit your dredger and the job at hand perfectly. It can be used for various types of dredging works, plus dumping and ground levelling jobs.

GPS with reference signals

The dredger is pinpointed on the map through a DGNSS Global Positioning System or a DGNSS-RTK position receiver. The RTK reference signals can be used to increase position accuracy.

Hopper dredge monitoring

Reliable, stand-alone dredge monitoring system

The dredge monitoring system provides operators with a real-time overview of a Trailing Suction Hopper Dredger’s dredging process. The highly flexible system is customised according to the vessel’s operational profile. It supports the dredge control system and increases operational efficiency.

Reliable and fuel-efficient system

Hopper dredgers can be fitted out with the dredge monitoring system. It provides the dredge master with a clear overview of the location of the trailing pipe, the various stages of the hopper loading process, the dredge pump production, and a logging and reporting module. The system consists of separate modules, which can be added as required in line with the vessel’s operations.

Trailing pipe position visualisation

The basic module of the dredge monitoring system is the trailing pipe position visualisation. Using inclinometers on the hinges, the exact drag head position and dredging depth is calculated and visualised. All other modules can easily be added, further enhancing the hopper dredger’s operations.

Flexible system configuration

The hopper dredge monitoring system is visualised on one screen, using an industrial PC running on Windows OS. The highly flexible system can be shown on multiple screens and in multiple locations, other modules can be added, and screens can be personalised by selecting specific preferred fields.

For retrofits and newbuilds

Both newbuild hoppers and existing ones can be fitted out with the dredge monitoring system. As a complete instrumentation package not only are the software and PC delivered, but also the various sensors for the trailing pipe hinges, the vessel’s draught, the positions of the gantries, swell compensator and overflows – the complete package.

Logging with data string output

All data in the trailing pipe module, loading module and production module can be logged. Combined with dredging statuses and tank volumes, accurate daily reports can be made. These can be sent to the relevant authorities when required to track the progress of the dredging work, or they can be used to optimise the overall dredging process.

Operational practicalities

The dredge monitoring system offers the possibility of investigating the sensor diagnostics. The operator can pinpoint the exact location of a signal failure. Moreover, remote access is integrated in the system; Damen Services can assist the operator when required. As a result, assistance is fast and cost-effective, reducing downtime to a minimum.

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |