Turn Key Cement Plant

We provide the cement technology such as VRM, ART & Grinding Technology, Grinding & mills technology, HRM etc. Intralogistic Solutions for: Conveying, Loading, Palletising, Packaging, Sortation, Baggage Handling. With Top world leading companies like BEUMER Group GmbH & Co. KG (Germany) and Gebr. Pfeiffer (Germany).

For more details visit: https://www.beumergroup.com/ and https://www.gebr-pfeiffer.com/

Loading & Unloading Solutions

Balanced Crane

SAVE UP TO 75 % ON OPERATING COSTS. Balance material handlers provide the foundation for an efficient, productive and cost-effective logistics system for scrap yards, ports and sawmills. Stationary balancer machines can cover a large area, replacing multiple mobile machines. Not only does this add logistical value, but it is also a plus in terms of occupational safety and reducing operating costs.

Pneumatic Unloader

Pneumatic self-unloading vessels are built specifically to handle powder cargoes such as cement.

Screw-Type Unloader

Mechanical system uses inlet feeder to reach into the materials while it is rotating, collecting and transporting materials to vertical screw conveyor by negative rotation.

Barge Loader

River and sea ships are loaded with different goods – this must be done quickly, safely and with optimum utilization of the available loading space.

Conveying Solutions

Troughed Belt Conveyors

Open troughed belt conveyors transport bulk goods for cement manufacture quickly across large distances and rough terrain.

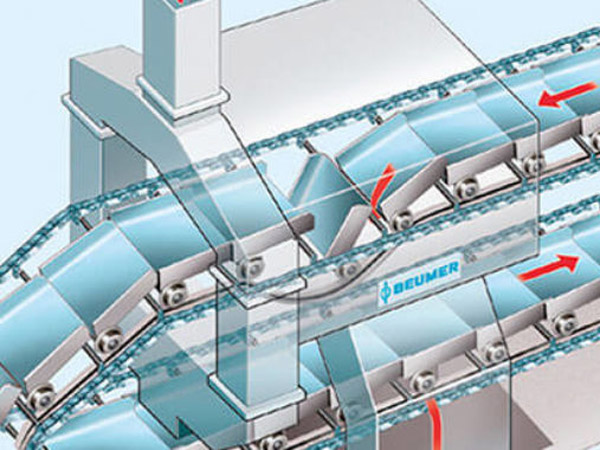

Pipe Conveyors

A pipe conveyor is recommended if sensitive products such as pulverised cement raw materials have to be protected against environmental influences.

Belt Bucket Elevators

Belt bucket elevators are required in many industries for the vertical transport of bulk materials.

Heavy-Duty Belt Bucket Elevators

The heavy duty belt bucket elevator was developed for use with coarse, highly abrasive bulk materials.

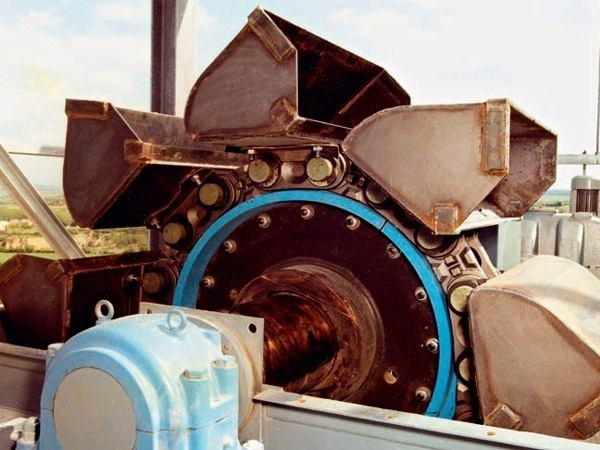

Chain Bucket Elevator

Chain bucket elevator developed expressly for maximum conveyor performance.

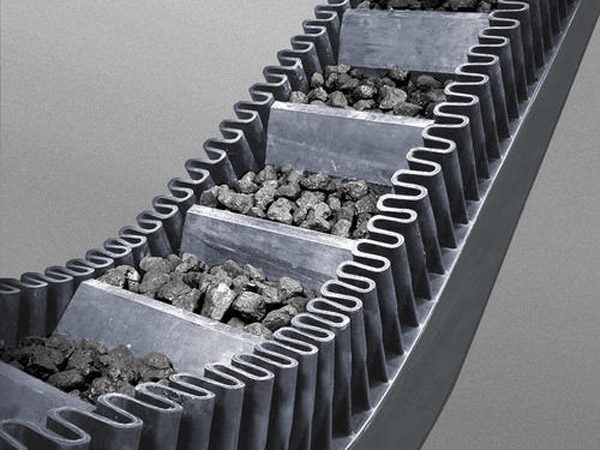

Apron Conveyors

Hot materials such as cement clinker can be transported using our apron conveyors with extra heat resistance.

Belt Apron Conveyors

The belt apron conveyor makes it possible to transport hot materials safely and economically at angles of incline of up to 60°.

Tipping Tray Conveyor

Flexible discharge of various bulk materials

Storage Solutions

Flat Bottom Silos

This silo is used for both short-term and long-term storage of grain.

Hopper Silos

The stored product stays off the ground to prevent moisture and lower the possibility of breakage.

Weighing Solutions

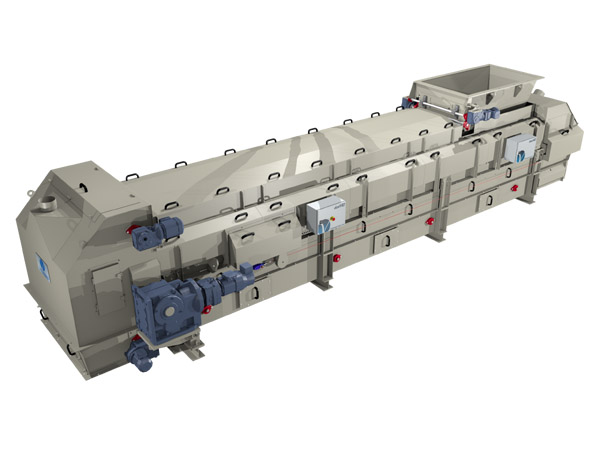

Belt Weigh Feeder

Regulates precisely the insertion of alternative fuels in cement kilns.

Grinding

Vertical Roller Mill

We are Presenting Multi Drive and Conventional Both Type of SolutionThe VRM is a vertically placed large sized machine which is equipped with some rollers used for grinding raw material.

Ball Mill

The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the ball mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding.

Industrial Fan Solutions

ID Fan

Centrifugal and axial fans are used in cement production process which has its own typical complexity, such as remarkable dimensions, high temperatures, accumulation of dust, abrasiveness of the fluid and the need for a high output solution. As explained above, we list some typical applications.

Packing Solutions

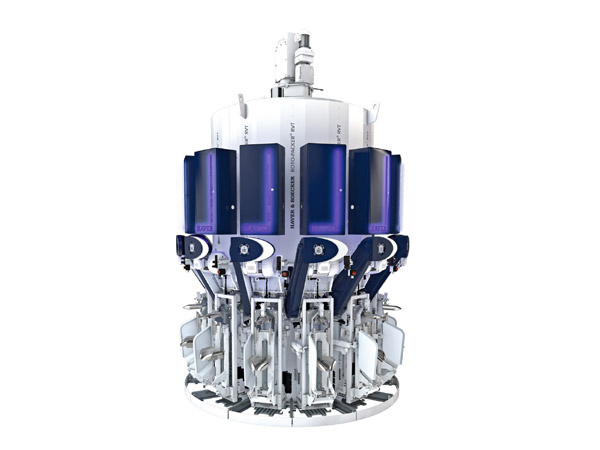

Rotary Packers

Electronic rotary packers are cleaner and safer than manual alternatives, and much more productive.

test2

test

asadsdsds

Meet Our Experts

- Address: KA-6/A, Navana Sylvania Baridhara, Dhaka, Bangladesh

- Phone: (+88) 01729065584, (+88) 01977646434

- Email: [email protected] , [email protected]

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |