BANGLAMARK provides complete turnkey solution for LPG Cylinder Manufacturing Plant. Starting from Blanking line up to finishing line BANGLAMARK offers wide range of equipment and designs for your required LPG cylinder. Our Turnkey solution is for the production of two- or three-piece steal LPG cylinders, mainly EN and DOT types, according to all relevant international standards. Main points of our turnkey solutions we offer for production of all kinds of LPG cylinders, particularly picnic, domestic and industrial types, are detailed below.

- LPG Cylinder Body Production Line

- LPG Cylinder Foot Ring and Collar Ring Production Line

- LPG Cylinder Degreasing Unit

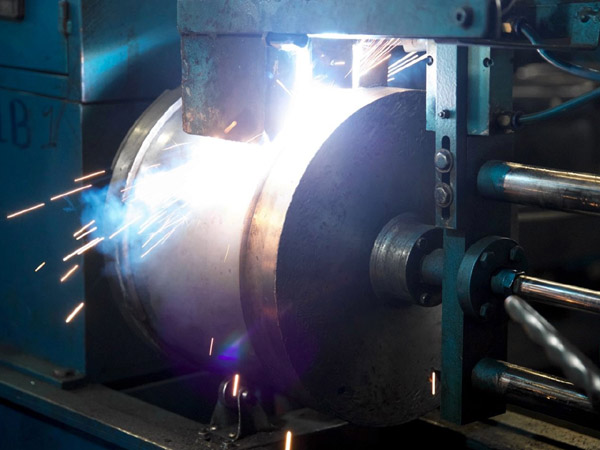

- LPG Cylinder Welding Line

- LPG Cylinder Heat Treatment Unit

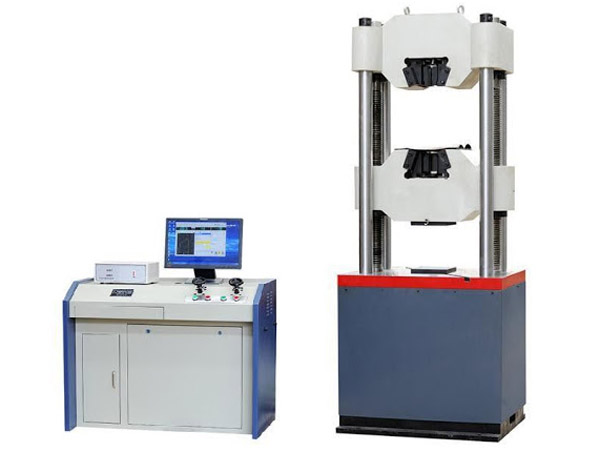

- LPG Cylinder Hydrostatic Test Unit

- LPG Cylinder Surface Preparation and Coating Line

- LPG Cylinder Test and Valve Assembly Line