-

Marine Fender

Marine Fender

Marine Fender

In boating, a fender is a bumper used to absorb the kinetic energy of a boat or vessel berthing against a jetty, quay wall or other vessel. Fenders, used on all types of vessels, from cargo ships to cruise ships, ferries and personal yachts, prevent damage to vessels and berthing structures. To do this, fenders have high energy absorption and low reaction force. Fenders are typically manufactured out of rubber, foam elastomer or plastic. Rubber fenders are either extruded or made in a mold. The type of fender that is most suitable for an application depends on many variables, including dimensions and displacement of the vessel, maximum allowable stand-off, berthing structure, tidal variations and other berth-specific conditions. The size of the fender unit is based on the berthing energy of the vessel which is related to the square of the berthing velocity.

Cone Fender

Cone Fender is the modified version Cell Fender combining excellent energy capacity with low reaction force to give the most efficient performance of any fender type. The conical shape keeps the fender body stable under all combinations of axial, shear and angular loading.

Core Attributes:

- Highly efficient shape

- Excellent under large berthing angles and shear

- Versatile design suits numerous applications

- Choice of standard & intermediate compounds

- Stable geometry maintains performance under all loading combinations

Arch Fenders

The arch fender is a V-type arch fender that has been optimized for increased energy absorption compared to traditional arch fenders.

Core Attributes:

- Rugged single piece moulding for long service life

- Strong bolting arrangement is easy and quick to install

- Excellent shear resistance means shear chains rarely needed

- Large range of sizes, lengths and Energy Indices

Cylindrical Fenders

Cylindrical fender is commonly used to ensure a safe and linear berthing for different kinds of vessels. Cylindrical rubber fender is an economical solution to protect most berthing structures. The simple structure makes it easy for installation and maintenance.

Core Attributes:

- Cylindrical fenders have simple and economical design, easy to install

- Choice of mounting systems to suit different structures and applications

- Sizes from 150mm to 2000mm diameter in almost any length

- Thick fender wall resists abrasion, even after years of heavy use

- Progressive load-deflection characteristics

Super Cell Fenders

This fender has a hollow cylindrical body with fully rubber-imbedded mounting flanges and is designed to deflect in an axial direction.

Core Attributes:

- Low reaction force; high capability of energy absorption.

- High force absorption and long usage life.

- Super cell fenders are high technical products developed to substitute common cell fenders. The rated compression reaches 55% and the E/R.H is 15% higher than E/R.H of common cell fenders.

- two types front panel, closed and opened. Closed panel has longer service life and better anti-corrosion than opened panel. It could be designed as per client’s requirements.

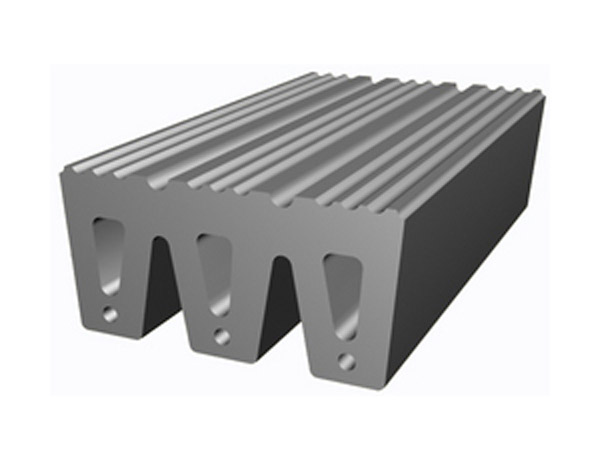

Unit Element Fender

Unit Element Fender which is also called element fender or leg fender is a high performance, modular system. It has been widly used across the world for decades. The construction of the unit element fender is simple but very strong and durable. They can provide good protection for piers and docks. The simplest and most popular Unit Element Fender system is the UE-V fender. It employs pair(s) of elements and a structural UHMW-PE facing pad. UE-V fenders combine high energy capacity with low friction face and high wear resistance. The versatility of Unit Element fenders makes them suitable for almost all applications.

Core Attributes:

- Modular design allows limitless setting out arrangements

- Excellent shear resistance in lengthwise plane

- UE-V fender shields can be bolted from the front using asymmetric elements

- Sizes to suit every application

- Easy and quick to install

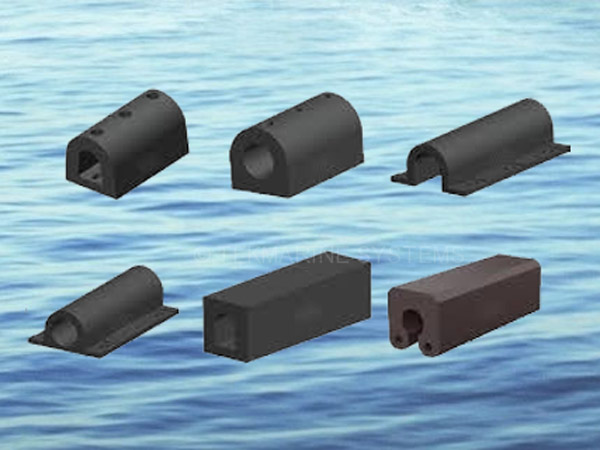

D Fender

D fenders are the commonly used rubber bumpers across the world and they are produced by means of extrusion in an extensive range of designs and sizes. The flat back of this type of fender facilitates the easy installation of D fenders on various surfaces for the protection of ships and docks.

Core Attributes:

- Ideal for smaller quays and wharves

- Easy to install with a flat bar down the bore

- Can be supplied in long lengths and be cut to length, angle cut at the ends

Pneumatic Rubber Fender

The Pneumatic Fender is an abrasion-resistant rubber fender filled with high pressure air. It can easily be deflated which allows simple and cost-effective relocation and re-commissioning in other locations.

Square Fenders

Square fenders are produced in various designs and sizes and they can be used for a wide range of purposes. The production takes place by means of extrusion. When compared to D- fenders, square fenders are used when a more rigid and stronger bumper is required for use in more severe conditions.

Core Attributes:

- Ideal for tougher service environments

- Easy to be mounted quay by means of anchor belts

- Can be supplied in long lengths and be cut to length, angle cut at the ends

Wing Fender

Wing Fenders are developed on the basis of D Fenders. They can be fixed with double line anchors which greatly increase the installation stability. Furthermore, their anchoring bolt is bigger than D Fender so that the anchoring grip is double to D Fender. Usually wing fenders are used as an alternative to other profiles as beltings for tugs and workboats. Instead of drilling the fender, the wings of wing fender are retained by steel angles.

Core Attributes:

- The reaction force and energy absorption of wing fender are higher than D fender

- Compact size and expedient installation due to the “wing” design

- Wing Fender enlarge fender bottom width and pre-built-in steel plate mount.

- Particularly applicable for framework quay, in addition the wing fender can be arranged and used with other types of rubber fender.

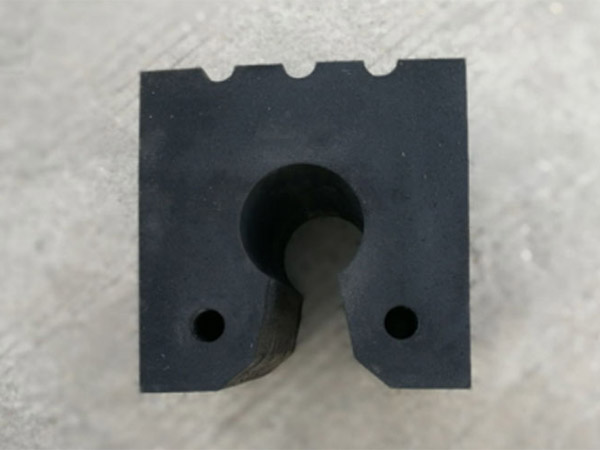

Keyhole Fender

Keyhole Fender is made of high abrasion resistance rubber. They are specially designed for tugboats and workboats. Keyhole Fenders are very easy to install and maintain. The two mounting holes facilitate easy and accurate installation. As with other extruded fenders Keyhole Fenders can be offered with an UHMW-PE Facing Pad. The simplicity of installation make this type of fender a highly economical solution. The Keyhole Fenders are normally installed using the bolt on method. They are available in 100H to 400H and length as per customer requirement. (Custom Made Rubber Fenders)

Core Attributes:

- Highly resistant to degradation, UV radiation.

- Reliable protection for the bow of a vessel.

- Heavy duty construction.

- Very easy to install and replace.

- Available in a wild range of sizes.

Foam Filled Fender

Foam Filled Fender is versatile, robust and suitable for almost all applications. The manufacturing process allows for virtually any size of fender to be constructed and selecting the appropriate grade of foam core and elastomeric skin means the performance of a fender can be precisely gauged to meet specific specification requirements. Characteristically Foam Filled Fenders have a high energy absorption compared to their reactive load meaning they are ideal for existing structures and certain hull types such as catamarans and cruise ships

The Foam Filled Fenders are constructed of three parts each providing an important function in the construction and lifespan of the fender. The three parts are

- The closed cell EVA foam.

- Outer rubber + nylon cord fabrics.

- Polyurea spraying coat.

Thug Fender

Tug fenders must work harder, for longer and under more adverse conditions than any other fender type. Tug fenders can be divided into three main types, (i) W-Fender, (ii) M-Fender and (iii) Tugboat Fender.

W Fenders: W Type Rubber Fenders are specially designed as vertical fenders for the bow and stern of tugs. The unique profile of W Fender is able to accommodate the tight radius and closely follow the ship’s contours

M Fenders: M Type Rubber Fenders are also used for pushing. They provide a large flat contact face for very low hull pressures – useful when working with soft hulled ships such as tankers and bulk carriers. The grooved profile gives extra grip and the M Fender can easily be mounted around on straight sections and fairly small radii at the bow and stern quarters of a tug.

Tugboat Fenders: Tugboat Rubber Fenders are made of high abrasion resistance rubber with good resilience properties for required applications. These fenders are easy to install and dismantle with users friendly fixtures, tool tackles. They are very popular with small port craft owners and tug owners. They are compression molded in high pressure thermic fluid heated moulds and have excellent sea water resistance. These fenders also have excellent resistance to ozone aging and UV rays, which enhances their life under severe working conditions

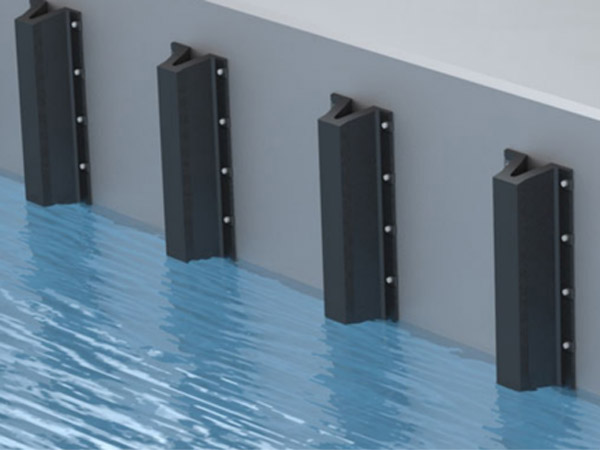

Roller Wheel Fender

Roller Wheel Fenders are commonly used on the berth corners and dock entrances. They are also widely installed along the walls of dry docks and other restricted channels to help guide vessels and prevent hull damage. They can be divided into two types, Roller Fender and Wheel Fender. Roller Fenders are commonly installed along the walls of dry docks and other restricted channels to help guide vessels and prevent hull damage. Roller Fenders are also used on berth corners and lock entrances where lower energy capacity is required. Wheel Fenders help vessels manoeuvre into berths and narrow channels. Different configurations are used for a variety of locations such as locks and dry dock entrances and exposed corners.

Rubber Ladders

Rubber Ladders are very robust. They are flexible to reduce accidental damage and help protect the wharf from small craft berthing. The Modular Rubber Ladders are corrosion resistant. They can withstand most accidental impacts from smaller vessels. Rubber Ladder Fenders come in two configurations. One is be produced in stainless steel. The other one is molded rubber. And they are very easily fitted to steel and concrete structures. Available in a wild range of lengths, rubber ladders can also be fitted with a rubber encased chain extension to suit overhanging structures.

Meet Our Experts

- Address: KA-6/A, Navana Sylvania Baridhara, Dhaka, Bangladesh

- Phone: (+88) 01878907462, (+88) 01977646434

- Email: [email protected] , [email protected]

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |