-

Oil & Gas Product Solution (ProSol)

Oil & Gas Product Solution (ProSol) -

Oil & Gas Product Solution (ProSol)

Oil & Gas Product Solution (ProSol)

Oil & Gas Product Solution (ProSol)

The BANGLAMARK Prosol Division is renowned for supplying oil & gas-related equipment and turnkey solutions with an excellent track record. Our goal is to serve all of our customers as a One-Stop-Shop for all the oil & gas related equipment. Our extensive network of leading suppliers of oil & gas components allows us to offer you high-quality products for any oil & gas-related purposes at competitive prices, completely hassle-free, and with short delivery times. We have never compromised on the quality and the services provided to the customers. At a glance, BANGLAMARK prosol can be your lifetime trusted partner for your existing and upcoming oil & gas industry.

Second Sun Tank Heaters

Second Sun™ is a flameless catalytic tank heater designed to safely and efficiently augment natural vaporization in propane, LPG and anhydrous ammonia storage tanks. When our environment is unable to supply the needed energy, Second Sun is an ideal solution!

Why The Second Sun?

- No Flame − no source of ignition!

- Gas powered − utilizes propane vapor from the storage tank for operation of the heater and monitoring controls

- Catalytic Heater − low temperature radiant heat will not overheat or harm the tank surface

- Self contained, off-grid operation

- 30,000 btu/hr input

- Adds 2.2 mm btu/hr of vaporization

- Equipped with safety controls for high pressure and high temperature

- High pressure safety switch monitors the pressure in the tank being heated

- Two high temperature switches monitor the temperature of the tank surfac

- Designed to fit 41″-84″ diameter tanks, 1,000 gallons and larger, up to 12,000 gallons

- Simple to install − 2 person install

- Easy to remove for tank and heater inspection

- Meets hazardous location requirements

- Can be used with Propane, Butane or LPG

Applications

- Boost pressure in the LPG storage tank

- Increase tank vaporization

- Replace a liquid pump in a vaporizer application

- Boost pressure in a storage tank that has been overdrawn and refrigerated

- Butane tank heater

How Does It Work?

The SECOND SUN is a propane tank heater that operates based on tank pressure. The tank heater utilizes an adjustable operating pressure switch with a range of 55 psi − 100 psi. When the pressure in the storage tank falls below the operating switch set point the heater will cycle on providing heat (energy) into the liquid stored in the tank. When the pressure requirement is satisfied, the tank heater reverts to a standby mode.

An integral 12V DC heater is used to initially start the SECOND SUN. After being started, the power source is no longer required.

The Heating Process

Catalytic heating is a flameless process that involves chemical reactions aided by a catalyst. The reaction starts on an electrically heated catalyst surface causing complex molecules to rearrange as simpler molecular structures.The primary byproduct of this catalytic process is heat. Second Sun emits this heat against the surface of the tank as infrared waves similar to a radiant heater. This warm, low intensity heat mimics the energy from the sun. Since catalytic heating is flameless, Second Sun meets hazardous location requirements.

Operational Overview

Second Sun’s typical application involves maintaining tank pressure, or equilibrium pressure, as vapor is extracted. Consequently, the unit’s ‘ON’ cycle is activated based on storage tank pressure. As vapor is consumed or the ambient temperature drops, tank pressure is reduced. Second Sun is activated ‘ON’ when tank pressure falls below approximately 50 PSIG (3.45 barg); Second Sun returns to standby when pressure is restored to 60 PSIG (4.14 barg).

Second Sun requires no AC electricity! Startup power for the catalytic reaction is provided using “jumper cables” integral to the unit to supply 12 VDC from a service vehicle battery. After startup, sufficient voltage to operate the gas security valve is ‘self-generated’ by employing a physical phenomenon known as thermoelectric effect.

This technique provides direct conversion of temperature differentials to electric voltage. The heater is comprised of an integrated “pilot” and “main” heater. The pilot heater starts the catalyzing process; the main heater provides operational heat. It could not be simpler!

Two temperature safety switches — upper and lower — both integral to the Second Sun, monitor the tank surface temperature and control the heater output. When the liquid level in the tank drops below the location of the upper switch on the tank surface, the main heater will switch to stand-by mode. If the liquid level in the tank drops below the location of the lower switch the heater will shut off entirely requiring manual restart. If the pilot heater temperature drops below the temperature necessary to catalyze the fuel, the catalytic reaction ceases and the heater will automatically shut down, again requiring manual restart.

Consta-MIX

Algas-SDI Consta-MIX™ systems are used to dilute natural gas or LPG with air for augmenting the supply of digester gas to run standard and low emission stationary reciprocating engine generators, and for pre-mixing natural gas or LP-gas with air for combustion applications. The Consta-MIX valve is a proprietary zero pressure mixing valve with two sets of cones and orifices that control the flow rate of each gas to a specific mixing ratio. A vernier adjustment slide allows finite adjustment and gives high tolerance control of the gas quality throughout the entire flow range. Ideal for: waste water treatment plants, landfill gas users, glass factory forehearths, and other combustion process that benefit from uniform mixing and even heat distribution instead of nozzle mixing.

- Natural Gas Air Mixing System

- Complete natuaral gas/air mixing system includes Consta Mix mixing valve, Eclipse blower and zero governor.

- Available up to 5 PSIG delivery pressure.

- Capacities range from 560,000 BTU/Hr – 7,850,000 BTU/Hr.

- 100 to 1 turndown (with cooling loop).

- Perfect mixer for burner pre-mix applications or digester gas replacement for generating electricity at wastewater treatment plants.

- Special epoxy coated systems also available for mixing digester gas with natural gas.

Hose

Hose Introduction

BANGLAMARK Prosol offers Elaflex hoses which is one of the leading international specialist for refueling equipment and safe connections for the transfer of dangerous goods and sensitive fluids.

Since the foundation in 1923 Elalfex has been developed into a leading specialist for engineered refueling equipment. Refuelling calls for the highest standards of safety, consequently Elaflex mission is to offer premium quality only. Their competent design and engineering departments and production facilities safeguard that Elaflex products are technologically state of the art, in accordance with the highest safety measures and set standards in the industry sector

Elaflex hoses, fittings, couplings, expansion joints and nozzles have been setting standards, since 1923. Along with Elaflex We provide quality engineered durable products. A sound investment both in terms of performance and total lifetime cost benefits.

LPG Hose

'Orange Band' Liquefied Petroleum Gas hose to EN 1762. For propane, butane and their mixtures to EN 589. As the hose lining is resistant to diffusion the hose is also suitable for natural gas. Use with propene (propylene) possible - pricking required. Not suitable for ammonia. Rugged and long-lasting construction with low tensile braids. Permitted working pressure 25 bar, burst pressure >100 bar. Temperature range -40°C up to +70°C (Special type LPG-LT does not crack down to -50°C). Approved by DVGW, approval No. DG-4621 AU 0049.

Lining: Nitrile rubber (NBR), black, electrically conductive, diffusion resistant

Reinforcements: Textile braids with 2 crossed tinned copper strands

Cover: Chloroprene (CR), black, electr. conductive, flame and abrasion resistant, ozone, UV and ageing resistant

Assembly and tests: For L.P. Gas hoses only suitable safety fittings acc. to EN 14422 or EN 14424 must be used which can be mounted tightly, see examples below. According to EN 1762, hose assembling must include a mandatory pressure and conductivity test

Industrial Valve

BANGLAMARK Prosol offers a wide variety of industrial valves and services for Power, Oil & Gas, Chemical and Refinery industry. We have different types of gate, globe, plug, ball, butterfly, check, pressure relief, control valves etc. These valves can be operated by handles, gears or actuators according to specific needs.

Ball Valve:

Ball valves are used to start, stop or throttle flow. It uses a ball shaped disk with a hole in it. When the valve is opened the hole of disk is turned in-line with the direction of the flow. When the valve is shut, the ball is rotated so that the hole is perpendicular to flow direction.

Butterfly Valve

Butterfly valves that can be used in on-off and throttling systems. They are quick and easy to operate. The flow control element is on either a vertical or horizontal axis and is opened when the handle is rotated 90 degrees and closed when the valve is turned an additional 90 degrees.

Check Valve

Check valves are used in systems employing gate valves because they prevent the reversal of flow in the piping system and there is a low pressure drop across the valve. The pressure of the fluid through the system opens the system, while the weight of the check mechanism will close the valve if the flow is reversed.

Safety Relief Valve

A relief valve opens slowly as the pressure increases about the set-point and only opens as necessary. A safety valve rapidly opens as the pressure setting is reached and will stay open until the pressure is lower than the actuating pressure set-point. Both valves are used to prevent damage by relieving accidental over- pressurized fluid systems.

LPG Road Tanker

Introduction

BANGLAMARK offers a wide range of LPG Gas Tanker which are extensively used in diverse industries to transport LPG from one place to the other. Fabricated from finest grade material, these tanks can suitably store liquids and gases under high pressures and are highly durable, sturdy and resistant to corrosion. Our range is available in varied specifications and can also be custom designed as per clients' requirements.

SEMI-TRAILERS

All of our offered semitrailers are manufactured according T-PED Directive and ADR standards, ASME VIII upon customer requirement and design. It’s not the customer who needs to adapt to our product, we need to provide the customer what he actually needs in its everyday activity. We can supply straight cylindrical or gooseneck LPG semitrailers, with pneumatic or mechanical suspensions, with one, two, three or four axles, lateral or rear transfer cabinet, single or twin tires.

BOBTAILS

Our offered bobtails are installed on all main truck brands and with several possible options. Volume capacity may vary from 3 to 40m3, depending on truck and national legislation. Also for bobtails our designed is depending on end user needs and country, with stiff and robust anchoring design for off-road and bad road conditions, aluminum baffles and light anchor system for maximized payload in Western countries. Standard scope of supply is composed by a fixed tank and a transfer and metering plant with LPG pump, volumetric meter and delivery hose reel.

These are some of the possible options:

- Demountable unit (with twist-locks)

- Rear cabinet in fiberglass or lateral in aluminium

- Vapor & liquid recovery piston compressor (or blade type for liquid only)

- Vapor hose reel

- ATEX approved emergency and/or control wireless system

- Mass/vortex/turbine meters with electronic register

- Flow sight indicator on filling line

Metering System

BANGLAMARK Offers flow measurement, control and communications solutions, serving commercial and industrial needs nationwide. Our products are used to measure the flow of LPG and are known for accuracy, long-lasting durability and for providing valuable and timely measurement data. Our smart solutions allow users to optimize, use and minimize waste of one of the world’s most precious resources.

LPG Mass Flow Meter:

The Mass Flow Meter is used to measure the mass of LPG consumed in each of the applications in the manufacturing process. The system includes either digital or analog thermal mass flow meters, controllers, and switches. A Coriolis flow meter contains a tube which is energized by a fixed vibration. Due to the moving mass and Coriolis Effect, the inlet and outlet sections oscillate in different directions causing the highly sensitive sensors to pick up these changes. This gives a direct measure of the flow of liquid or gas in the pipe.

Positive Displacement Liquid Flow Meter:

Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid or gas by dividing the media into fixed, metered volumes; finite increments or volumes of the fluid. Positive Displacement flow meters are the only flow measuring technology to directly measure the volume of fluid that passes though the flow meter. It achieves this by trapping pockets of fluid between rotating components housed within a high precision chamber. Rotor rotational velocity is directly proportional to flow rate, since the flow of fluid is causing the rotation. In electronic flow meters the rotating components contain magnets that activate various sensor options located outside the fluid chamber. Mechanical positive displacement flow sensors rely on the rotation to drive either a magnetic coupling or a direct gear train connected to the mechanical counter.

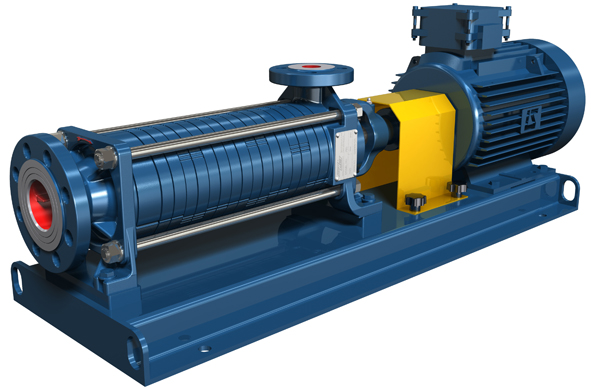

Pump System

Intro

BANGLAMARK offers various types of Liquid LPG pumps which are used in LPG systems to transfer product from one tank to another, or to supply LPG to a process that consumes it. Transfer from transport trucks into stationary storage tanks is often completed using a truck-mounted liquid pump. Many LPG vapor systems and LPG-Air systems also utilize pumps to ensure adequate product pressure.

Truck Loading/Unloading Pump:

Liquefied Petroleum Gas (LPG) has to be transshipped and stored temporarily several times from the production up to final destination at customer site. The transport tank is connected to a hose and pumps are used to transfer the liquid LPG from a storage tank to the road tanker. Required amount of LPG is then carried in a truck mounted tank to the destination.

Tank Loading/Unloading Pump:

LPG storage tank loading/unloading is similar to that of the truck loading/unloading. Before the transfer begins, pressure is equalized between the storage tank and the road tanker. When the pump is started, it pulls liquefied LPG from the bottom of the tanker, through the pump, and to the storage tank. As the tank fills with liquefied gas, accumulated vapor is passively transferred from the storage tank to the transport tank. The transfer process is complete when the tanker is emptied.

LPG Filling Pump:

Horizontal, self-priming centrifugal pumps of the segmental type with closed impellers and a suction stage. The suction stage is installed at discharge side. It is arranged in parallel to the last liquid handling stage and operates acc. to the sucking-through principle. The design UEA has an axial inlet with NPSH inducer stage. The axial thrust is compensated by single-impeller relief. The remaining axial thrust are compensated by antifriction bearings of sufficient size. A hydraulically favourable re-routing is done by means of guiding devices in the stage casings.

Reticulation System

Reticulated System Intro

BANGLAMARK Prosol offers quality equipment for LPG Reticulated System which is and advanced method of supplying LPG to households. As compared to the conventional cylinder supply LPG Reticulated system is a piped network that supplies cooking gas to individual flats through a centralized Bulk Storage or gas bank/cylinder bank facility. We also have our own expertise to provide installation services for LPG Reticulated System.

Diaphragm Gas Meters

BANGLAMARK offers Accurate, reliable and secure diaphragm gas meters. Our offered Gas Meters impress by the sound processing of high-quality materials combined with a large number of technical details. These meters are made with the materials of the highest quality that meet the requirements for product lifetime, security and technical precision. For example, our offered diaphragm gas meters are made of high quality steel plate or aluminium alloy. The seal plate is made of stainless steel and resistant to corrosion.

Performance characteristics

- Approved in accordance with MID by NMi

- Wide measuring range for flow rates of 0.016 m³/h to 6 m³/h

- Galvanized steel powder-coated housing for maximum corrosion

- resistance

- Fire resistant (HTB) up to 0.1 bar according to EN1359

- Maximum pressure loss: < 160 Pa at flowrates of 6 m³/h

- Starting flow < 1 dm³/h

- Integrated system to adjust the error curve

- Working temperature range: -25 °C to +55 °C

- Operating pressure: 0.5 bar

- Long-term stability due to usage of high-quality diaphragms

- Retrofittable with pulser

- Optional: reverse flow preventer

First Stage Regulator

BANGLAMARK offers High Pressure Industrial / Commercial Regulators which is designed to reduce propane gas container pressure down to between 3 and 100 PSIG. Ideal for liquid or vapor service, they can be used in a variety of applications including salamander heaters, weed burning torches, fish cookers, tar pot heaters, and other industrial type services.

Features

• Provides high capacity performance at a reasonable price.

• Suitable for both liquid and vapor service.

• Compact design provides for easy installation.

• Negative or indirect acting design provides for excellent performance when needed most – in cold weather, when tank pressures are lowest and system demands are highest.

• Consistent delivery pressure, especially in cold weather, helps ensure maximum performance from the second stage regulator.

• Can be readily fitted with a pressure gauge in the ¼” F.NPT port.

• Molded diaphragm provides an o-ring like seal between the body and the bonnet.

• Fully painted in brilliant red for complete corrosion protection.

• Available in four adjustable ranges for maximum performance.

• Bonnet and body are assembled in the USA using the unique,

patented RegULok™ Seal System.

Second Stage Regulator

BANGLAMARK offers Low Pressure Second Stage Regulators - Standard Settings which is designed to reduce first stage pressure of 5 to 20 PSIG down to burner pressure, normally 11” w.c. Ideal for medium commercial installations, multiple cylinder installations and normal domestic loads

Features

• Large vent helps prevent blockage and has ¾" F.NPT for vent piping.

• With 15 PSIG inlet pressure, regulator is designed to not pass more than 2 PSIG with the seat disc removed.

• Incorporates integral relief valves.

• Replaceable valve orifice and valve seat disc.

Vaporizer

BANGLAMARK offers Algas-SDI vaporizers which are safe, simple and reliable thus allowing the LP-Gas professional and end user the peace of mind and freedom to focus on what they do best. Our offered vaporizers are designed with decades of experience with LPG and various conditions all around the world. When you use an Algas-SDI vaporizer you are using the best!

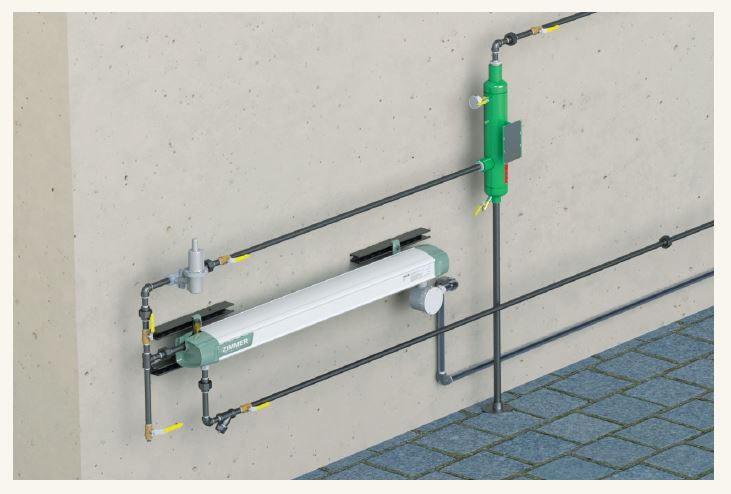

ZIMMER™ Electric LPG Vaporizer

If low cost of ownership of a vaporizer is important to you or your customers, Algas-SDI, the pioneer in dry-electric vaporizers, has the solution for you. Dry-electric means more reliable operation and less maintenance when compared to other vaporizer types. The ZIMMER requires almost zero maintenance. In the event that the vaporizer becomes clogged for any reason, it can be easily cleaned on-site without removal.

The technology behind the dry-electric ZIMMER is advanced, yet simple to operate. Algas-SDI innovated every element of the ZIMMER design ensuring years of safe, reliable, affordable, and easy-to-use LPG vaporization.

- Hands Down the Most Reliable and Trouble-free Vaporizer Available

- Energy-Efficient, Self-Modulating Heaters – Only Uses the Required Energy

- Easy Access to All Maintainable Components

- Dry-Electric Design – No Water, No Glycol to Maintain

- Aluminum Construction – Corrosion Free

- Easy to Install – Multiple Mounting Options

- 25 to 150 kg/hr* – Easily add in parallel for even Greater Capacities

- Start-up in less than 60 seconds – LPG vapor when you need it

TORREXX™ Electric LPG Vaporizer

TORREXX™ fills the application niche where 3-phase power is available and eliminates the corrosion, evaporation and frequent ‘shut-downs’ associated with electric waterbaths. TORREXX defines the industrial standard for dry electric LPG and NH3 vaporizers. A robust 135amp rated contactor provides power to the heating elements. The modular temperature controller allows easy maintenance or replacement. In the event of a “high liquid level occurrence,” our proprietary Liqui-Safe Valve™ prevents liquid LPG from passing downstream of the vaporizer. The valve provides visual indication of activation. This allows easy troubleshooting and assures the enduser the device is functioning properly.

Set your mind at ease and deliver the reliability of LP-Gas that your customer expects with Algas-SDI’s latest electric vaporizer-the TORREXX! Designed with both the discriminating LP-Gas professional and end-user in mind, the TORREXX raises the bar in performance, safety, and reliability. Compact, highly efficient, and extremely durable, the TORREXX is poised to become the new industry standard for electric vaporizers.

- Proprietary Liqui-SAFE™ Valve positively prevents liquid carry-over and provides visual indication when tripped.

- Unsurpassed reliability through simplified and more robust controls; thermocouple temperature sensor, no start/stop switches to complicate field wiring.

- Heavy duty 135 amp contactor increases life, and reduces maintenance.

- Replaceable temperature controller with adjustable set point.

- Thermocouple temperature sensor increases life and reduces maintenance.

- Withstands momentary power interruptions without service disruption.

- Hazardous area classification – Class I, Division 1, and Zone 1.

- Dry electric design requires no water or glycol.

- 98% thermal efficiency.

- Operates on any LPG mixture from 100% propane to 100% butane.

- Perfect for any climate – rated to -40 F./ -40 C.

- Ready for operation in less than one minute.

- Optional economy operation valve – allows vaporizer use only when needed. Pressure activated. Can be field installed on any unit up to 160 GPH. No electricity required.

LPG Reticulated System

LPG Reticulation system is a system where LPG Cylinders are stored in form of Gas Bank in a safe area. Then LP Gas is supplied to the kitchen trough piping network. This system has multiple pressure regulation stages to supply LPG to user at low pressure and to make the system safer.

Benefit of Reticulation system:

For Residents:

1. Continuous supply of gas at the turn of tap.

2. No need for cylinder booking and handling.

3. Easy operation and increased convenience.

4. Increased safety in the kitchen as piped gas pressure is a fraction of cylinder pressure.

5. Piped system is safe and convenient.

6. Valuable space saving inside the kitchen by not having cylinder.

7. System based on modern technology.

8. Payment as per actual consumption of gas through meter after usage.

9. No worry of less gas in LPG cylinders.

Packaged SNG Systems

Much like a generator for electricity back-up, ASDI’s Packaged (propane-air) Systems provide a complete solution for backing up Natural Gas. Simply connect to the fuel storage vessel and the natural gas piping feeding the process load. Systems sizes range from 5MMBtu/hr to more than 1Billion Btu/hr. Industrial systems are designed and manufactured in accordance with NFPA 58 while municipal utility systems are designed and manufactured in accordance with NFPA 59. Most models and packages carry third party listings (Factory Mutual) for ease of local acceptance.

Synthetic Natural Gas systems can be used to augment or completely replace piped natural gas, compressed natural gas or liquefied natural gas to manage outages, interruptions in supply or to capture price advantages between different fuel types. Algas-SDI manufactures a complete range of natural gas replacement systems for industrial and municipal applications, including hospitals, schools, military bases and emergency shelters. Large utility systems are designed and manufactured for LDC peak load shaving after the city gate. Systems can be supplied in either high or low pressure configurations with high pressure systems requiring a compressed air source. Algas-SDI has the widest range of vaporizer options available from direct gas fired, to gas fired waterbath to full dry electric vaporizers that can be turned on and ready in less than 60 seconds. Environmentally, propane air is a clean alternative to backing up your fuel energy needs. With more than 80 years in the propane industry worldwide, Algas-SDI stands ready to help.

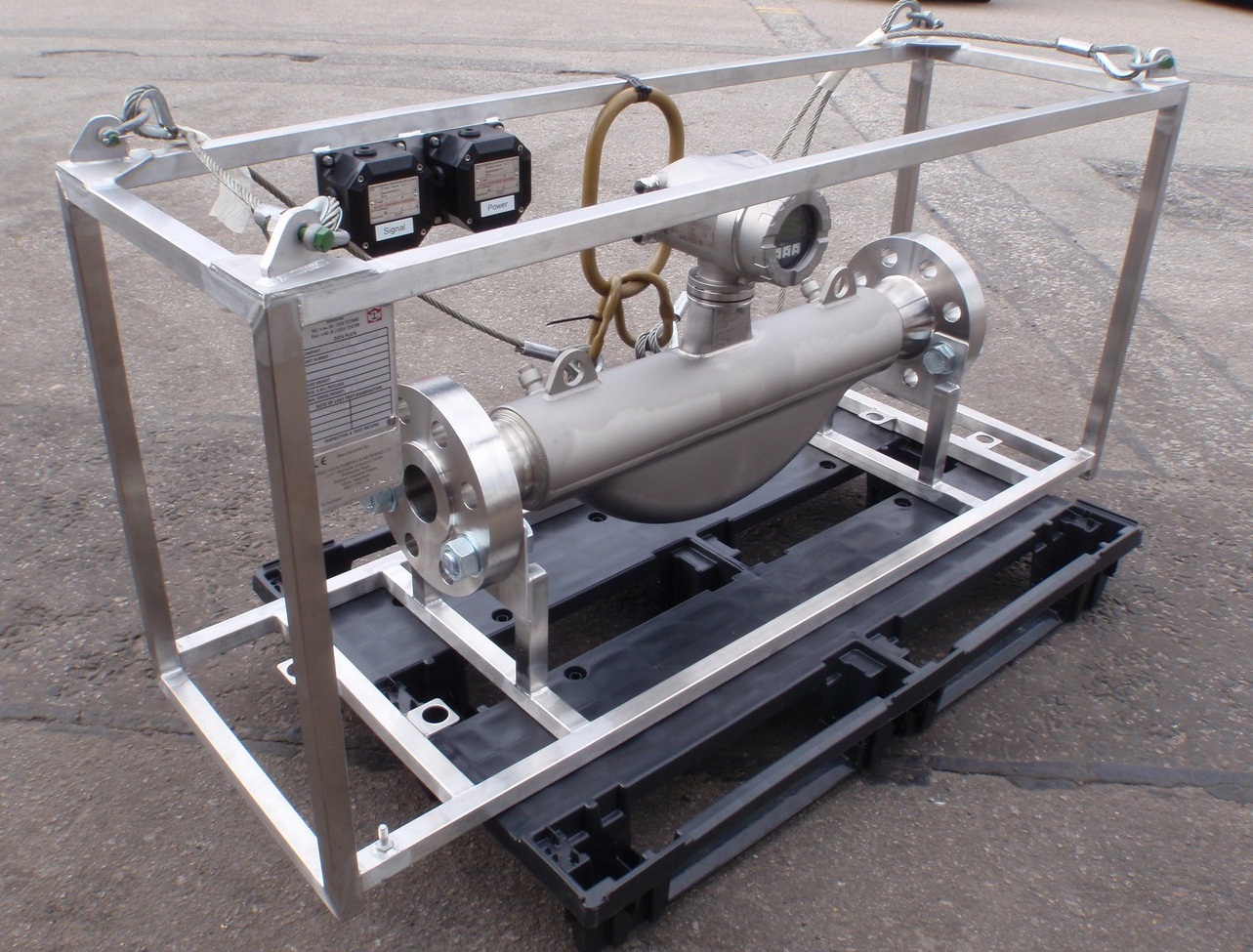

CNG TRUXX

Why TRUXX?

TRUXX is a fully functional CNG decanting system that gives end users access to natural gas as quickly and easily as possible with minimal downtime. The TRUXX CNG pressure-reduction units are ideal for commercial and industrial facilities, utilities, high-horsepower field-service companies, and others not connected to a pipeline.

TRUXX portable CNG decompression skids enable natural gas to start flowing in less than 6 hours after arriving on site. For TRUXX fixed locations, flow begins in 7 days.

Our systems address critical items for CNG suppliers, including:

- Low-cost installation

- Low heel pressure & inlet temperature

- Simple, reliable heat system

- Ease of maintenance

TRUXX deliver more than just natural gas:

Long-Term Value

TRUXX provides long-term value by incorporating features that minimize your continuing operating expenses. Our systems are designed, manufactured, and pre-tested to expedite and simplify installation on your site. Installation only requires a concrete pad (for fixed locations) and a small electrical source to begin flowing gas.

Increased Reliability

TRUXX ensures reliability, which means a predictable and reliable track record through well-proven standardized designs. All TRUXX units are designed and manufactured by our trained professional staff.

Easy Maintenance

Tired of crossing pipes and wires? The TRUXX G-Series was designed to allow ample space to service equipment.

Fewer Complexities

High pressures? Low temperatures? Variable flow rates? We considered all these conditions when designing TRUXX. As such, we removed potential obstacles that keep you from doing your business — moving natural gas.

- Standardized design of TRUXX units enables short lead times.

- Modular heating system allows incremental sizes up to 18,000 CFM.

- Two integral decanting posts to main unit reduce site installation costs. (TRUXX G-Series and TRUXX E-Series)

- Our unique pressure control design allows for a reliable and stable discharge pressure

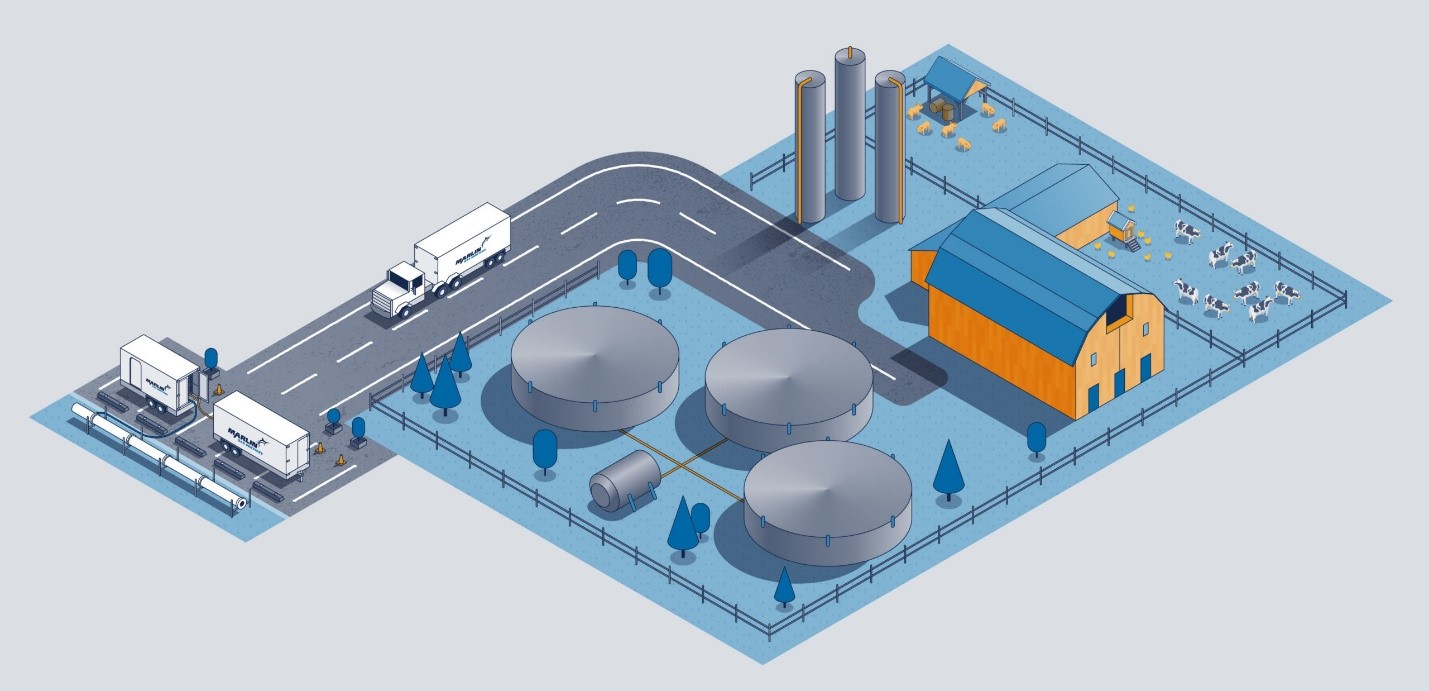

TRUXX Renewable Energy Solutions

Why RNG?

Algas-SDI’s methane injection systems are based on the well-proven TRUXX CNG platform. Waterbath gas or electric heated PRU’s blend Algas-SDI’s CNG systems experience at commercial through utility peaking systems with the measurement and controls necessary for continuous, reliable pipeline injection of gas generated from renewable resources.

TRUXX Compressed Natural Gas (CNG) Technologies

- Gas-Fired TRUXX G-Series – Portable and Fixed Installations

- Waterbath TRUXX W-Series – Portable and Fixed Installations

- CNG Learning Center

Biogas Mixing

Constamix and Blendaire mixing systems for sweetening/enrichening or diluting biogas for use in generators, boilers or other combustion processes. These systems are typically used at Landfill and Waste Water Treatment Plants (WWTP).

Customized Solutions

Our engineering staff have worked with many clients to customize a solution for their specific needs. We have extensive experience with Utility safety protocols. If your application requires Risk Assessments or Layers of Protection Analysis (LOPA) sessions to satisfy local jurisdiction requirements and operational safety protocols for the facilities we are here to assist in the process.

COMPEXX Compact Explosion-Proof Dry Electric Process Heater

COMPEXX ™ is intended for process heating applications requiring up to 40 kW power. The modular design allows for single- or multi-unit configurations.

Utilizing electric heating elements cast “in-situ” into an Aluminum core, COMPEXX ™ eliminates the need for water/glycol and circulation pumps making this “dry design” simple and corrosion-free.

The Process fluid itself is contained within a 316 SS coil also cast into the aluminum heater block. Two thermocouples control normal operation and provide over-temperature protection.

Meet Our Experts

- Address: KA-6/A, Navana Sylvania Baridhara, Dhaka, Bangladesh

- Phone: 01729065620, 01977646434

- Email: [email protected] , [email protected]

Download Section

| Document Title | Download |

Video Section

| Video Title | Play |